Home>Roll forming

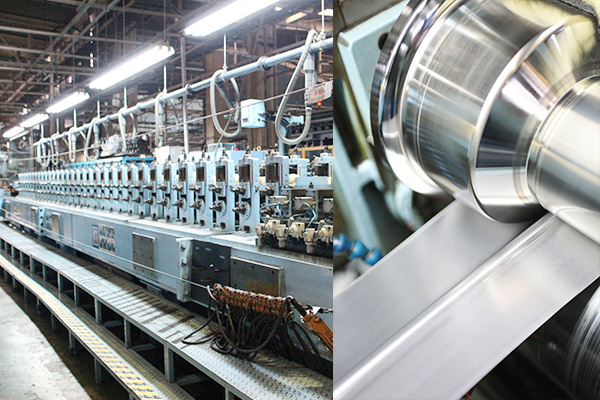

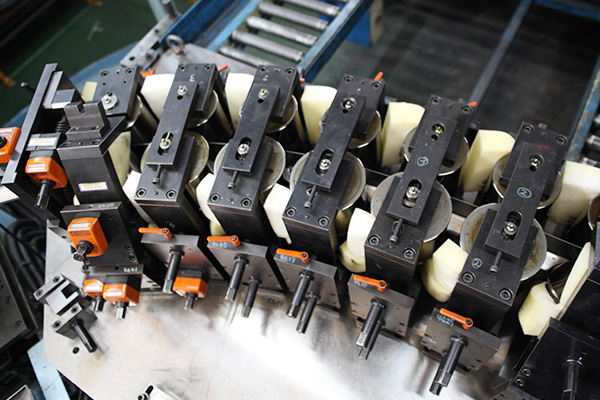

A line of several roll pieces with differing shapes gradually form a belt-shaped sheet of steel. The number of rolls is from 10 to 50 and increases as the shape becomes more complex.

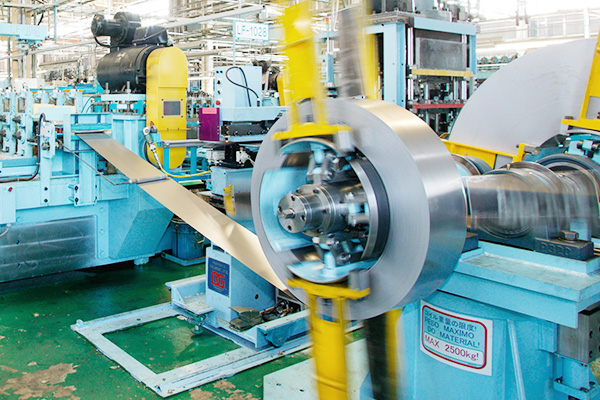

Supplies hoops to the roll forming machine at a stable speed.

Forms plates into a complex constant profile.

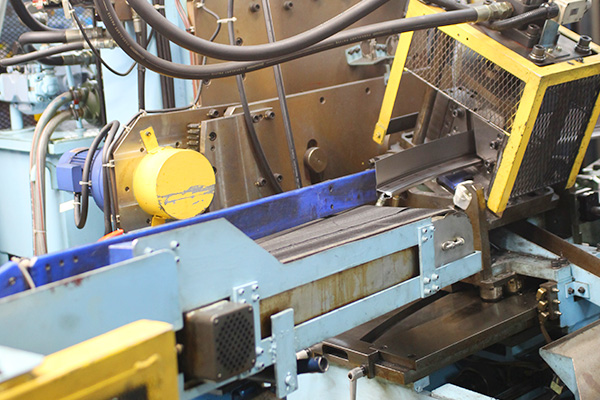

Maintains shapes by welding them in a specified position so that the profile retains its shape.

Performs two-dimensional and three-dimensional bending.

Guarantees full product length by cutting at synchronized roll speeds.

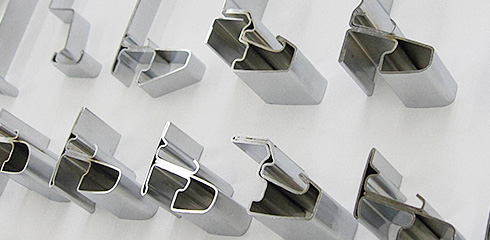

We are experienced in producing various plate thicknesses, materials, sizes, profile types.

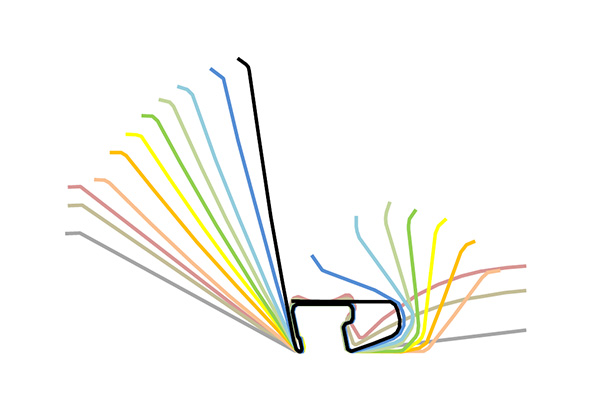

Roll flower pattern (example)

Roll flower pattern (example)Constant profiles can be formed continuously by passing steel between a line of roll forming pieces.